Singular vs. serial design

Who do you design for and what goal do you want to achieve? Important questions at the beginning of any design assignment. These are also the first questions we ask the customer. When this is clear, you can propose much more targeted solutions. The design freedoms and limitations are also determined by, among other things, the number you want to make.

Do you want to design something for your neighbor who has trouble lifting his walker over the doorstep? Or did you find a solution to a very universal problem? In other words, is your solution scalable for the general public or is it something specific? The answer to this question determines whether you are to use standard parts or whether you design everything yourself so that you are not dependent on the stock of the Gamma.

You can probably already state that our customers mainly want products that have to be produced in larger numbers. The size of these numbers can vary from 600 pieces per year to 600 pieces per day. This also leads to choices in production methods and design directions. Although 600 pieces per year is already on the high side, you could still mill or laser cut depending on the shape. At 600 pieces per day, this is no longer economically viable. This does not mean that we do not use these types of production methods on a smaller scale. In the development phase, prototypes are indispensable and methods such as milling, laser cutting or 3D printing are ideal for this. These methods are a relatively inexpensive way to see if something is going to work and what it looks like.

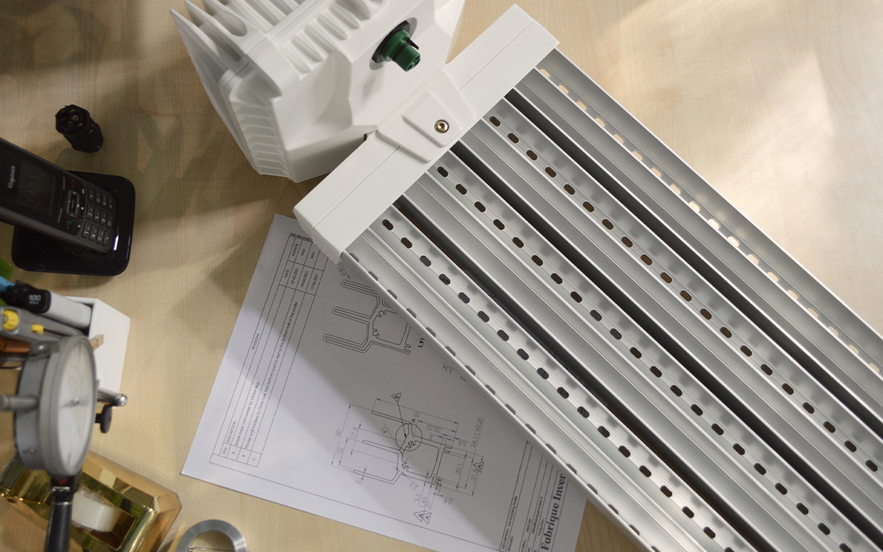

At Fabrique Invent we design many extrusion profiles and high-pressure casting parts. These are methods in which you can produce large volumes and in which you can ultimately keep the unit price low. Casting products are known for their profitability at high volumes, but there are also casting methods that lend themselves perfectly to smaller volumes, such as rotational casting, sand casting or low pressure casting. All these methods have their own design rules. For example, the required draft angles can play a major role in the shape, which is not always desirable. But wall thicknesses and wall thickness differences in the product also depend on this. Wall thicknesses are of great importance for the design. It ensures manufacturability, the strength and rigidity of the product. It largely determines the weight of the part and thus the price. You can imagine that a good designer wants to be able to explain every millimeter or tenths of millimeters of wall thickness. When you make 600 pieces a day of these parts, every gram counts.

Another aspect that complicates the design profession are composed products. By that I mean multi-part products, which is pretty much any product. For example, a simple ballpoint pen easily consists of 10 parts. How do you ensure that all these 10 parts always fit together? Assuming a ballpoint pen will be assembled completely by machine, what if the top half of the pen doesn't fit on the bottom half? This would stop the entire assembly line.

This all has to do with taking tolerances into account. Each production method has a different degree of accuracy. Ensuring that all tolerances are taken into account is one of the most difficult challenges of the design profession. You have a tolerance on wall thicknesses, openings, flatness, roundness, parallelism, and so on. Then materials can also be hard or soft, which can also complicate assembly.

Not every design agency deals with this, but at Fabrique Invent this is one of our most important added value. We design the parts in such a way that they can be deposited with different production companies and you are not at the mercy of 1 party that can make it. This ensures flexibility and continuity. For example, suppose you have a product consisting of 10 parts and you had to find 10 different manufacturers for this. Then it is extremely important that you have calculated correctly that the parts always fit together, even when they are made on the edge of tolerance. It often happens that producer A has no idea of the part that is made by producer B. Meaning the producers cannot take each other into account. This responsibility rests on the shoulders of the designer.

To achieve this and to unburden the client, we often contact the chosen producer to agree what is feasible for them and what is acceptable to us. When all the parts have arrived, it is therefore a great sight when it turns out as you planned. In our design methodology, it is also important not to forget about the product when the drawings have been sent to the manufacturer, but to assemble the first parts yourself and watch them in the assembly hall. In the end, this is where you really find out whether the theory is true in practice!

This article is written by Mike de Jong. Mike is sr. industrial designer at Fabrique Invent.

The known paths and beyond.

The design process explained with climbing a mountain as a metaphor.

Aluminum alloys in product design.

We list the different alloys and how we implement them in our designs.